Difference between revisions of "Quantar UHF RX conversion"

(Created page with "This is the first method of converting the Quantar UHF Receiver. It's provided for reference only. == R1 to R2 == The basic premise of converting the R1 to a R2 is four maj...") |

|||

| Line 1: | Line 1: | ||

| − | This is the first method of converting the Quantar UHF Receiver. It's provided for reference only. | + | This is the first method of converting the [[UHF Receiver|Quantar UHF Receiver]]. It's provided for reference only. |

== R1 to R2 == | == R1 to R2 == | ||

Latest revision as of 03:33, 27 March 2024

This is the first method of converting the Quantar UHF Receiver. It's provided for reference only.

Contents

R1 to R2

The basic premise of converting the R1 to a R2 is four major parts:

- Convert the VCO for the proper frequency coverage

- Modify the Image filter

- Change the module ID

- Modify preselector

It's important to have a known good working unit on R1 before starting work. If it is not working at it's intended frequency, fix it first.

It would be good to become very familiar with the schematic and service manual before attempting this.

Tools and test equipment you should have (not an exhaustive list)

- Hot air station

- Under board pre-heater

- High quality soldering iron (metcal)

- Dual voltage variable DC supply

- Spectrum analyzer and probes

- Service monitor

- Experience working with SMD and reflow techniques

Converting VCO

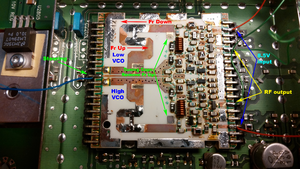

IC2200 is a sealed unit containing two VCO's.

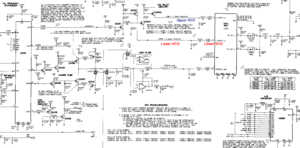

Check out the schematic! The Diagram is wrong when it shows the upper and lower VCO!

The VCO substrate is ceramic, and sensitive to thermal shock, so be careful about this, as it will crack. I prefer to leave the VCO in place attached to the pins supporting it on the main PCB while working on it. To do this means the copper case must come off in one piece with out letting the board drop from the pins. Obviously the problem with this is to get the VCO hot enough to remove the case will cause the pins to reflow as well.

Prior to preheating I fashion supports out of aluminum foil or other material and jam them between the PCB and the underside of the VCO. I find one at the bottom middle and two on the top corners is sufficient. It's important there be some slight upward tension on the PCB from these supports. This will prevent the VCO board from falling off it's pins when removing the shield.

Once this is done, mask off the area using hole cut in some foil. This is a heat shield for the other parts of the board. Some times you need to use kapton tape to secure the foil in place.

Setup the board with an under board pre-heater set to 460f. This is important as you want the board to warm up to close to the melting point of solder. Then the hot air wand will heat it the rest of the way.

Once you have this preheated for a few minutes, use the hot air wand with no tip 15 L/m and 650f on the shield. Move it in a circular pattern while waiting on it to reflow. A dental pick is a good test for reflow, be aware the solder will not all flow at the same time.

Once it's flowed while keeping the heat moving on the VCO case, pull the case straight up with some needle nose pliers. The case should come clean off, though you may need to rock it back and forth a bit. Careful you don't disturb any of the VCO parts, as they will most likely be reflowed. If you do, don't panic, just look at the before picture and put everything back to how it was on the VCO. It's a pretty easy circuit to figure out.

Now the VCO should be exposed and you can tack on some test wires to it while it cools down.

Hook up to the VCO as shown, we'll do the Low VCO first.

- 8.5 V power to high and low VCO (not at the same time).

- 0-12 V on the steering line.

- output loops of wire on the VCO output. These are to be looped around a probe and into a spectrum analyzer to view the output.

A few points about VCO tuning:

- The VCO will be 73.35 MHz higher than the intended receiver frequency

- the sweet spot for the VCO steering voltage is 2.5-7.5 v

- each VCO is designed to cover half the range of the quantar.

- The Exciter will change VCO's when it hits the range's center frequency +25khz (UHF R2 is MHz) . You can verify this my looking at the steering voltage in the exciter as you change frequencies. A test config file (Codeplug) makes this easy.

- with the shield on they move up about 2.5 MHz

- from hot to cold Fr changes about 1.5 to 2 MHz. Hotter makes Fr go down, cool makes it go up.

- removing capacitance makes Fr go up.

- removing inductance makes Fr go up.

- tune a bit below the frequency (2 MHz) and adjust the tuning caps

- you may elect to move the center frequency lower on the lower VCO and higher on the high VCO if you desire a greater tuning range. I will not be showing this.

- Get it close, I'm a perfectionist, but really 1-2 MHz from idea will not matter.

- at higher steering voltages (>9v) the VCO may get dirty. This is normal.

Put 5.0v on the steering line and note the frequency on the spectrum analyzer. You can sweep it from low to high and check the coverage is correct per the table above (it will be about 2MHz higher with the case off).

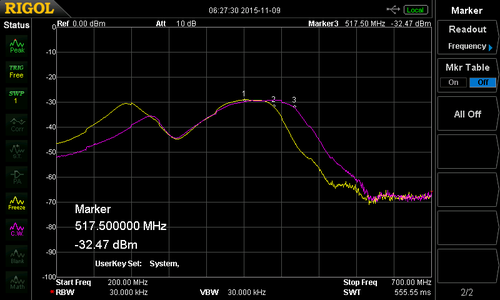

We're going to align it for a center frequency of 517 MHz. The reason for this is the lower VCO covers 511-527, making the center 519, but with the shield off we will see the CF be ~2 MHz lower. The shield adds capacitance to the circuit and this ups the resonate frequency.

With the voltage on the steering line, cut a 75 mill strip of .250 copper foil. It's not critical, you'll be adjusting it. Place it on the VCO Trombone to short out part of the strip-line. You can safely monitor the output of the VCO and move this at the same time. It's best to go lower than the center frequency we want. (515 MHz is a good point). Once you are within a few MHz, let the board cool. You'll find the Fr rising as it cools.

Moving the short closer to the trombone end lowers Fr, pulling it further away from the end raises Fr.

while monitoring the VCO output on the spectrum analyzer, use a diamond tip Dremmel grinder and remove some of the high impedance end tuning cap on the VCO. Go a very little at a time, it makes a big difference. Use this to bring the VCO frequency up to 517 MHz on the dot. It's normal for the VCO to jump a couple hundred KHZ or so depending on the stability of your power supply. There is no PLL running to lock it.

Do a sweep according the the service manual and ensure it covers the intended range for the Low VCO (again subtract 2 MHz from the intended range with the case off). You want the coverage to be in the sweet spot of 2.5v to 7.5v, if it's not re-adjust it.

The high VCO is the same, just on the side of the VCO closer to the edge of the main board (bottom). The center frequency for tuning the VCO is 533 MHz, meaning get it to 531 or so with with strip-line short and then let it cool. Once it's cooled trim up the capacitor with a the grinder to bring it on frequency.

Clean it with some solvent and let it dry.

- The case needs to be reinstalled so clean out the holes and set it in place.

- Make sure the wedges are still under the board and the protective foil mask is in place on the top side.

- Turn on the pre-heater and let it soak

- Use the hot air wand to reflow the board solder.

- Some light pressure on the shield may be needed to seat it, or some flux to reflow the old solder.

- Solder the under side of the board holes the shield goes into.

Let the VCO cool and test both sides of the VCO once cooled.

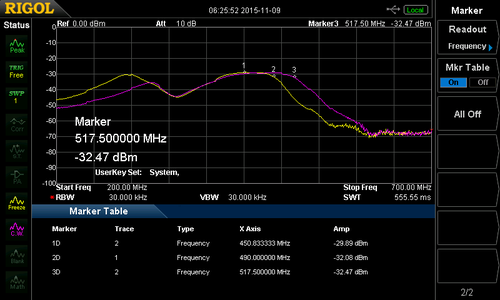

Below is real data from a R1 to R2 conversion. The before data was taken with the shield off making the frequency about 2 mhz lower. The pink represents the sweet spot of the VCO tuning voltages. Note this covers both VCO ranges acceptably.

| Before Mod (shield off) | After mod, Shield on | |||

|---|---|---|---|---|

| Volts | Low | High | Low | High |

| 0 | 450 | 465 | 491 | 508 |

| 1 | 456.5 | 472 | 498 | 516 |

| 2 | 462.5 | 478 | 504 | 521 |

| 3 | 467.5 | 483 | 509 | 527 |

| 4 | 472.5 | 488 | 514 | 531 |

| 5 | 477.5 | 492 | 518 | 536 |

| 6 | 482 | 497 | 522 | 539 |

| 7 | 487 | 501 | 526 | 543 |

| 8 | 491 | 505 | 530 | 547 |

| 9.2 | 496.5 | 510 | 535 | 552 |

| 10 | 500 | 513 | 537 | 555 |

| Delta | 50 | 48 | 46 | 47 |

Image filter

The image filter is a low pass filter which prevents the Local Oscillator from radiating out the receiver antenna port. This may be debatable as to the necessity of this modification as the cutoff of the R1 image filter is still above the maximum operating frequency of 470 MHz.

| Frequency | Befor mod | After Mod |

|---|---|---|

| 438.000 | -123.2 dBm | -123.5 dBm |

| 454.000 | -122.7 dBm | -123.1 dBm |

| 454.250 | -122.7 dBm | -123.1 dBm |

| 470.000 | -121.7 dBm | -122.4 dBm |

This is a spectrum plot of the R1 and R2 traces over laid on each other. R1 is in yellow and R2 is purple. As can be seen the R1 filter doesn't start attenuating the signal until 490 MHz, and since this is past the first amplifier stage, loss here is not a huge problem.

There is no difference in sensitivity, but all units which I convert I modify this for completeness.

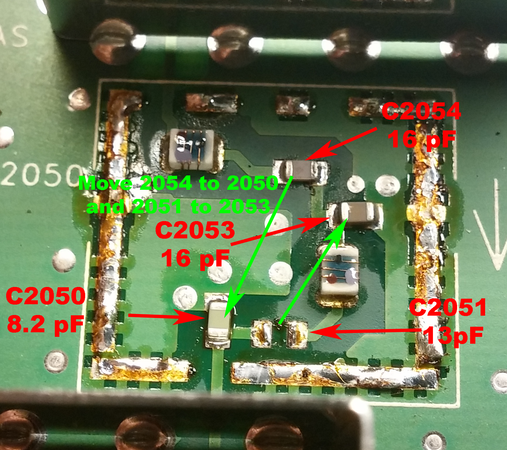

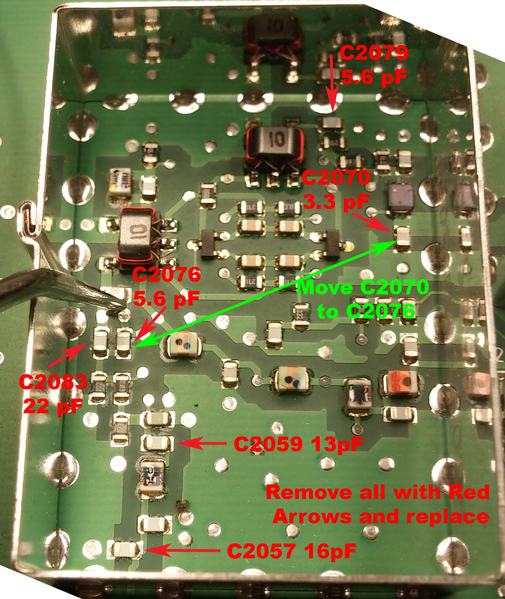

Below are the parts differences. All parts are NPO 0805 size ceramic parts. I remove all the "Discard" parts first and then move the couple parts since the board is already hot.

| Part number | R1 | R2 | Notes |

|---|---|---|---|

| C2050 | 9.1 pF | 8.2 pF | Discard |

| C2051 | 16pF | 13pF | move to C2053 |

| C2053 | 18 pF | 16 pF | Discard |

| C2054 | 8.2 pF | 6.8 pF | Move to C2050 |

| C2057 | 18 pF | 16 pF | Discard |

| C2059 | 18 pF | 13 pF | Discard |

| C2070 | 5.6 pF | 3.3 pF | Move to C2076 |

| C2076 | 7.54 pF | 5.6 pF | Discard |

| C2079 | 9.1 pF | 5.6 pF | Discard |

| C2083 | 47 pF | 22 pF | Discard |

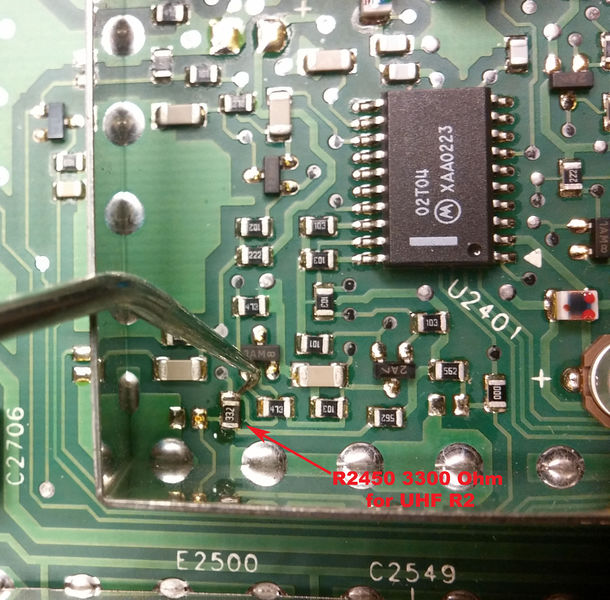

| R2449 | 0 Ohm | 0 Ohm | ID Leave |

| R2450 | 0 Ohm | 3300 Ohm | ID Replace |

Some parts (C2050-C2054) are under a soldered on shield cage between the preamplifer and the 1st mixer.

Using a board pre-heater and hot air wand remove the shield. It does not go through the board, but be careful you do not over heat it as the inductors will melt. It's much easier than the VCO shield. Once off change the parts per the table and reinstall the shield. Note the orientation of the shield, it's designed with cutouts on the input and output strip-lines.

- Change the parts under the 1st mixer shield per the table and picture below

Change the Module ID

There is one resistor, R2450 by the PLL synth which must be changed to a 3300 Ohm chip to set the RX type to R2.

Preselector

The preselector modifications are covered elsewhere.

Final testing

Once the preceding modifications have been done it's time to test the receiver module with out the preselctor.

With the power off install the RX board back in the metal case and slot it into the Quantar chassis.

Power the station on and program a test code plug with the following frequencies.

| Lock? | Steering voltage | Sensitivity | |

|---|---|---|---|

| 425.000 | |||

| 430.000 | |||

| 433.000 | |||

| 435.000 | |||

| 438.000 | |||

| 454.000 | |||

| 454.250 | |||

| 470.000 | |||

| 473.000 | |||

| 475.000 | |||

| 478.000 | |||

| 480.000 | |||

| 485.000 | |||

| 490.000 |

Use the control and metering screen to check the oscillator voltage at each frequency. Ideally you should be between 2 and 7.5 volts for 438.00-454.00 and 454.25-470. The other frequencies are there just to find the range of the VCO's as installed. If your minimum lock voltage is under 1.5v you may want to re-adjust the VCO in question. If the high frequency is above 8v you may wish to adjust as well.

Check the sensitivity of the receiver at all locked frequencies. With out the preselector installed the sensitivity should be better than -121.5 dBm or .2μV for 12dB SINAD.

Once this is verified, button it up, install the modified preselector and mark the unit as a R2 modified.

Congratulations!

R3 to R2

No data on this yet. Should be doable, VCO will be a problem.

R4 to R2

No data on this yet, may be doable VCO will be a problem.