Difference between revisions of "2020 Ram 1500 Radio Install"

| Line 120: | Line 120: | ||

<gallery widths=300pm heights=300px mode=packed> | <gallery widths=300pm heights=300px mode=packed> | ||

pocked mount breedlove with NMO and adapter.JPG | pocked mount breedlove with NMO and adapter.JPG | ||

| − | 900 and UHF | + | 900 and UHF-VHF antennas Final.JPG |

220 antenna pocket mount test.JPG | 220 antenna pocket mount test.JPG | ||

</gallery> | </gallery> | ||

Revision as of 05:39, 18 October 2020

I purchased a 2020 Ram 1500 Limited Ecodiesel, and have struggled to install a professional looking radio install in it. I don't want to have anything that would damage the vehicle (no bolts in the dash, etc.). Making it much more difficult is the vehicle is not really something which would be up-fitted with radios or lights for commercial use at this trim level. There's a 12" display and leather everywhere, so discreetly drilling a mount it will not be possible.

Radios to install

- 220 MHz Motorola CDM "1850" with remote head

- 440 MHz Motorola XTL2500 with O5 remote head

- 900 MHz Motorola XTL2500 with O3 Hand Held Control Head (HHCH)

- Blackview Dashcam

Goals for install

- Ignition sense for turning radios on/off

- Minimum impact to vehicle

- remote mount

- Single Speaker - this means a mixer will be built

- power directly from battery

- everything must enable expansion

Contents

Install Parts

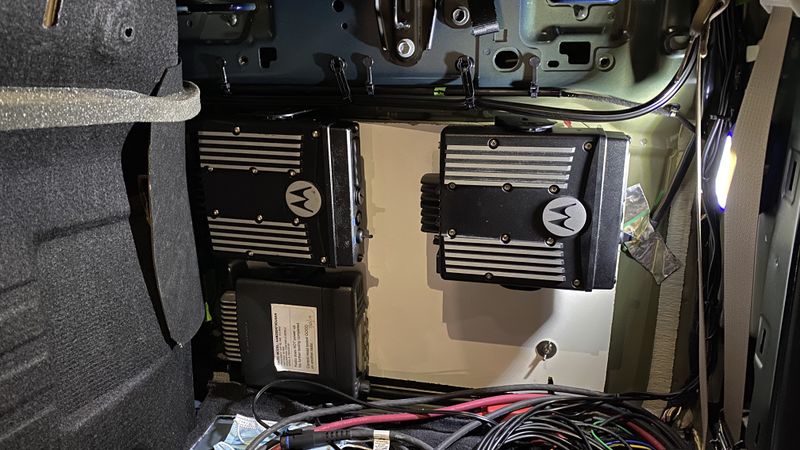

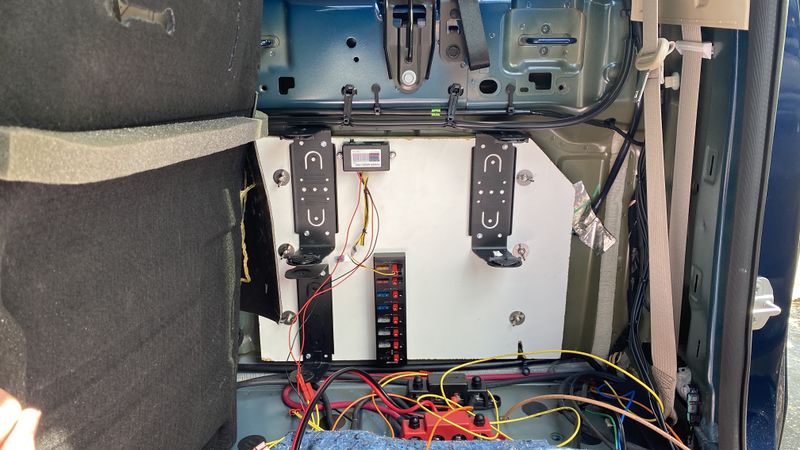

I decided to locate the radio decks on the rear drivers side wall of the truck. There is an ecoboost version of the gas engine which has an electric assist or some such thing. This means there's a large 48v battery pack located behind the rear drivers side seat in the cab. This is just over 6" of depth behind the seats, perfect for mounting radios.

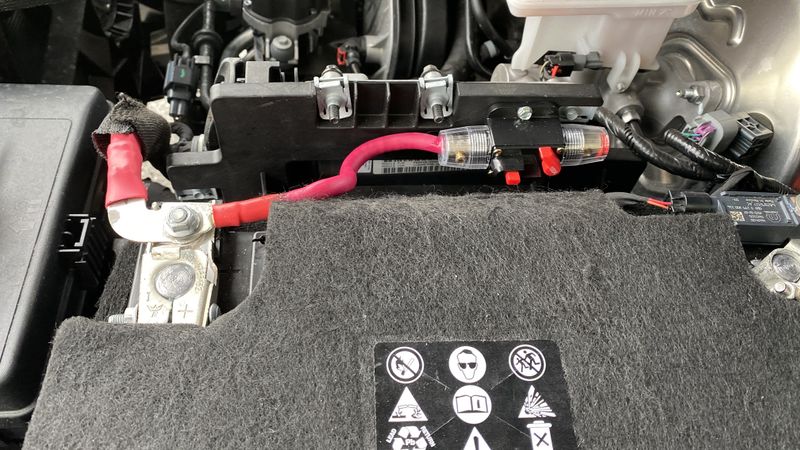

Battery

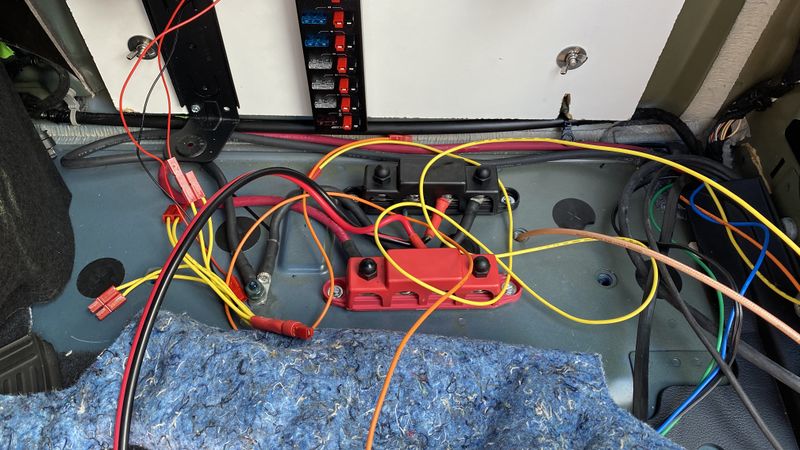

I decided to run a #2 wire to the battery via a 100 amp breaker. Welding cable was sourced from Skycraft Surplus in Orlando, along with lugs and such.

There's an easy to access rubber feed through grommet that fit the cables once a hole was poked through it. I only fused the positive side, as the negative will be tied to the ground in the rear of the cab. I bought 35' of cable, but only needed about 20', better to have too much than too little.

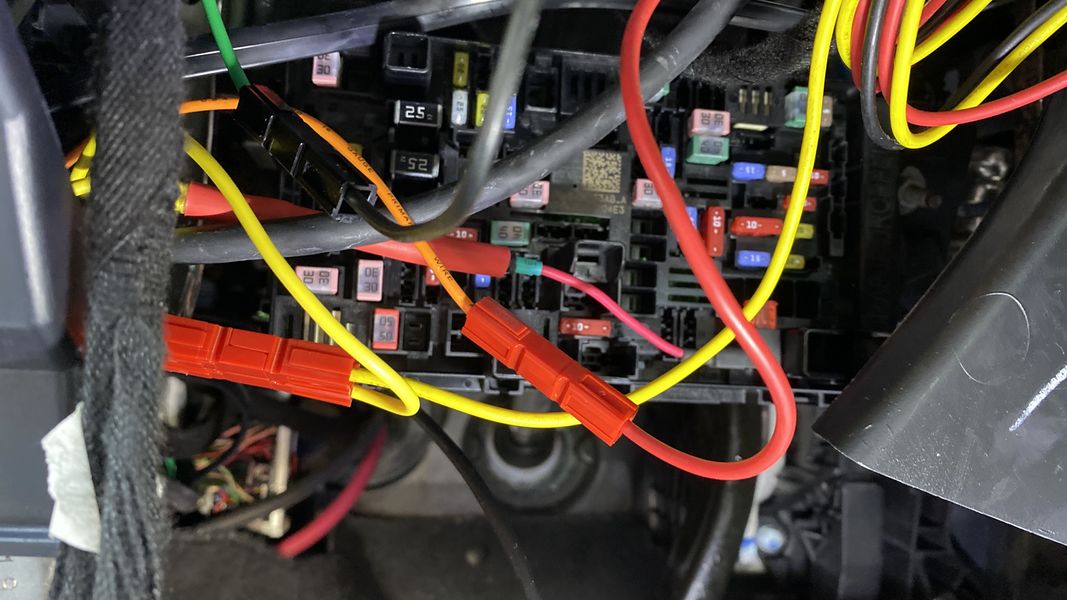

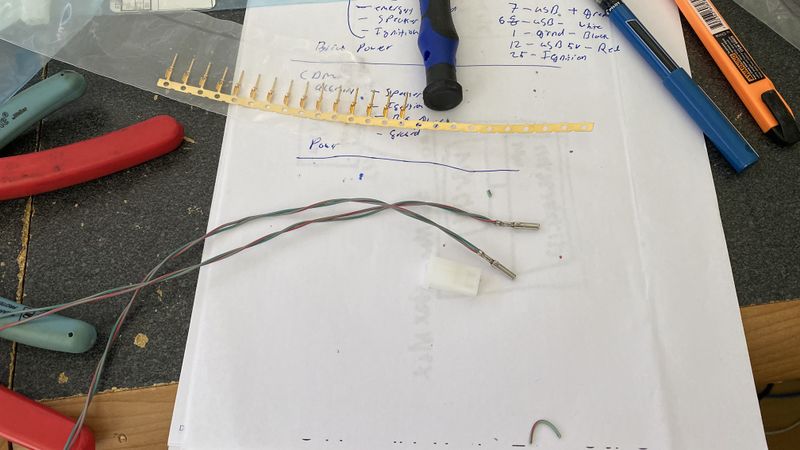

Ignition sense

The ignition sense was installed with a fuse tap in position 66 of the fuse block on the drivers side under the steering wheel. This was fused with a 5a fuse and I connected 3 power pole connectors to the output. One goes to the rear, one to the O5 head in the center console, and one is a spare. I used a lug with 4 black power poles as a ground point for the control heads too. This lug was installed on a 10mm bolt holding the fuse panel up. It tested to be a good ground point.

- Yellow wire is the ignition sense

- Red wire is B+ from back for control head.

- Blue and Green are unused

Rear Area

The decision was made to mount the radio to the rear wall of the cab behind the drivers rear seat. There was about 5" of room open here. The seat was easy to remove with a 14mm driver and a star driver.

I didn't want to drill holes through the rear cab wall for mounting the radio brackets due to weather proofing and rust issues. It occurred that mounting to a MDF board would work as I had the depth to work with. I would need a bracket to hold the board to the wall, something that would be removable even with the seat installed as I didn't want to have to remove the seat to service the radios.

My first idea was to make some brackets out of flat aluminum stock and bolts, but there was no easy way to secure the bolts to the stock as the bolts were stainless.

I moved to Stainless flat bar stock and used some 56% silver brazing rods to weld in 1/4" bolts. I mounted the brackets to the cab wall with 3M double sided tape. It's a concern this might fail, and if it does, I will upgrade to epoxy. I'd like to easily remove the brackets if I want to sell in the future.

- SS brackets 02.JPG

- SS brackets 03.JPG

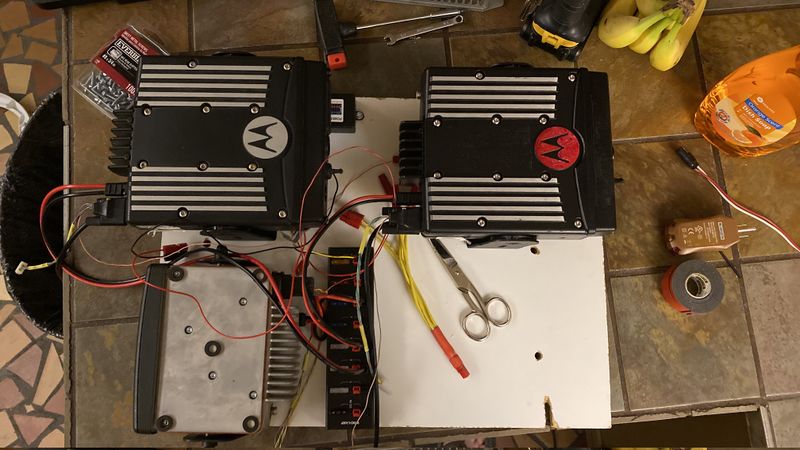

After this I cut some MDF board to fit and drilled it. Using wing nuts to secure it and some backing washers to level it out (the rear wall was not level between the brackets). I test fit the radios on the board to see it fit would hold. The red radio is the 900 and I also installed a 40 A powerpole fuse center too. I left space open for another radio.

The main #4 power cables were brought out to the bus bars I got from amazon. These were screwed into the floor metal under the carpet where there was a "hump" or free space. Importantly the negative cable was brought to the chassis ground before the bus bar to prevent a floating ground. The connectors were coated with silicone lube for good measure. In the future should an additional radio or connection need to be made, this provides a high amperage point to connect to.

As I wasn't going to have good access the the radios, I made up cable harness for them with built in programing cables.

Antenna Install

The antenna install was the most complex part of this project. My truck has a dual pane sunroof, retractable shade, side airbags and there's a whole drain system under the sunroof as well. All the cables need to be routed around this and there's a limited "flat" area on the roof to install an NMO.

Two NMO's were decided to be installed symmetrically about the center blade LTE/bcast/GPS antenna. The decision was made to drop the headliner, which was not easy but we did have diagrams of it in the FCA service manuals. Only the rear was dropped, which did cause a crease to appear near the middle A frame, but this went away when it was re-installed. In the future, I'd remove the A pillar plastic molding holding the headliner up if I was to do it again.

The first Idea was to use a comet tribander antenna with a triplexer, which meant I needed to rework the triplexer to RG-142 with mini-uhf connectors.

This Idea was abandoned when we saw the potential for a rigid antenna to cause the roof sheet metal to bend if it impacts something. I changed out the antennas to a VHF/UHF Tram Browning antenna on the passenger side and a super flexible whip for 900. This left 220 as the remaining band and a Breedlove mount was procured that fit in the pocket in the rear of the truck. The plastic did need to be trimmed to accommodate this. Breedlove doesn't offer a NMO base that uses an N connector for their mount so I brought a 5/8" one from Tram Browning. There was a 3/8" to NMO adapter needed for the Hustler 220 antenna too. When this was installed, the entire truck can be shaken from the mount; it is that secure.

Front Control and Mics

The center console in the Limited has a 12" LCD that's just behind tesla in screen size. Proclips makes a center mount that replaces the bottom of the compartment above the LCD. The two screws that are removed there are used to secure the screen module into the dash too. After some study I found the 12v lighter jack would be easy to remove and the XTL/control cables would pass though the hole.

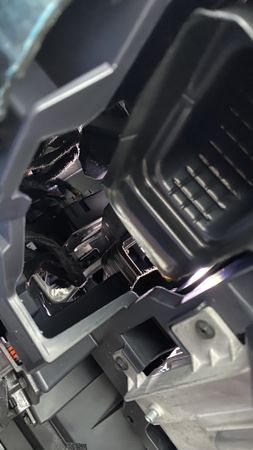

The 900 HHCH would be mounted on a proclip mount using a magnetic mic holder. The initial idea was to mount both the UHF mic and the HHCH 900 MHz to the clip, but this caused the UHF mic to come close to the steering wheel and was to much weight to support on the bracket. I'm still trying to figure out the best place to mount the mic for the UHF XTL. The HHCH wire was brought through the slot in the center console which a CD player can be installed in. In my truck it was just free space, like a pocket. Using a drill I was able to get a pilot hole and then use a key saw to open the back of it up. This fits the XTL connectors fine and keeps the HHCH wire from hitting my legs.

The head units were mounted on a LASER cut and bent bracket. This allowed access to the rear of the heads for the connector cables, while not having them stick out too far. The mount has thus far been quite robust. I do want to remove the protective film and paint it black, but it may be a good idea to have it roll over the top and bottom for extra rigidity before doing this.

<gallery widths=300pm heights=300px mode=packed> First Power up of Head Units.JPG <gallery>